A Breif Introduction On Glow In The Dark Glass

Glow in the dark mosaic and glow in the dark glass are new kinds of glow products that are very welcomed by customers from furniture and art industry. They can add a unique element into building/house decoration or into your art project. There are two ways to make glow in the dark mosaic: cold spray and hot meld.

This article will give a brief introduction on these two methods, from what kind of raw material you should source to details you should pay attention to during the production. Please note that these guidelines can only be referred to when using Zhejiang Minhui Luminous Techonology Co., Ltd (MINHUI)'s photoluminescent pigment. You may need to adjust certain parameteres during actual production.

Glow in the dark mosaic

Cold Spray

We will take a look at the operation of cold spray method first because it is relatively easy to manage. First and foremost, you need to mix the glow in the dark pigment and ink evenly. For this application, we recommend to choose transparent ink and photoluminescent pigment with smaller grain size, like MHG-6D, MHG-6E or MHG-4D, MHG-4E. If the ink you source is water-based ink, please choose our waterproof photoluminescent pigment.

We recommend the ratio of pigment to ink to be about 2:8 to 1:1 depending what level of luminosity you want to achieve. If the ratio exceeds 1:1, the increasing cost of raw material does not justify the increase of luminosity, and the mixture will be too thick to use.

When mixing the materials, please avoid contact with iron as much as possible, enamel or glass lined container are some of the alternatives. After the photoluminescent pigment and ink are thoroughly mixed, spray paint the mixture onto the glass surface for 2-3 times, and then sealed with a white layer.

Because glow in the dark pigment has a larger specific gravity, You should stir the photoluminescent ink while spraying, so that the sprayed ink will be more uniform and always contain a even amount of glow pigment. Otherwise, the luminous pigment will likely to precipitate and cause the sprayed ink to have less or none pigment. This will result in the final product to have poor or even zero glow.

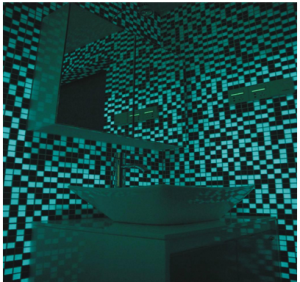

Glow in the dark bathroom (application of glow in the dark mosaic)

Hot Melt

As for the hot-melt process, it is more complicated than above method and involve the use of silk-screen printing and firing. Therefore, we recommend to use MCG-6B, MCG-6C or MCB-6B, MCB-6C. These models are from our MC series, which is specially developed for using in making ceramics and endure firing. MCG can withstand temperature as high as 850 Celsius (1562Fahrenheit). MCB can withstand temperature as high as 1050 Celsius (1922 Fahrenheit).

First of all, fully mix the glow in the dark pigment with the water-based ink. Again, please pay attention to avoid direct contact with iron during mixing. After the material is evenly mixed, use an 80-mesh screen to print 2-3 times on the tin surface of the glass. After printing the luminous layer, be sure to seal it with a white layer.

Then it can be fired after the ink is completely dry. During the firing process, try to keep the temperature below 800 Celsius. So the glow brightness of the final product will not be affected too much by the high temperature.

Post time: Aug-08-2022