MHG – Yellow Green Strontium Aluminate Photoluminescent Pigment

DESCRIPTION

MHG is strontium aluminate based photoluminescent pigment, with an apperance color of light yellow and a luminance color of yellow green. Our pigment is non-radioactive, non-toxic,very weatherproof, very chemically stable and with a long shelf life of 15 years.

We provide glow in the dark powder with multiple grain size, luminosity and price point to satisfy different industries' needs. For other colors of strontium aluminate based glow in the dark powder, please see: MHB blue-green, MHSB sky-blue, MHP purple, MT series. We also provide MHG in waterproof version.

SPECIFICATION

|

Model |

Size |

Afterglow Intensity |

Glowing color (Night) |

Appearance (Daytime) |

||

|

10 min |

60 min |

Glow time | ||||

|

MHG-6B |

65~85 |

725 |

120 |

>12 hour |

|

|

|

MHG-6C |

45~55 |

480 |

85 |

|||

|

MHG-6D |

25~35 |

380 |

55 |

|||

|

MHG-6E |

5~15 |

280 |

39 |

|||

|

MHG-6F |

2~10 |

240 |

30 |

|||

|

MHG-4B |

65~85 |

640 |

105 |

|||

|

MHG-4C |

45~55 |

450 |

70 |

|||

|

MHG-4D |

25~35 |

320 |

42 |

|||

|

MHG-4E |

5~15 |

220 |

29 |

|||

|

MHG-4F |

2~10 |

190 |

23 |

|||

|

MHG-2C |

55~75 |

350 |

40 |

|||

|

MHG-2D |

15~45 |

250 |

32 |

|||

|

MHG-1C |

55~75 |

260 |

35 |

10hour | ||

|

MHG-1D |

15~40 |

200 |

25 |

|||

Note:

1. Luminance test conditions: D65 standard light source at 1000LX luminous flux density for 10min of excitation.

2. Particle size B is recommended for production craft of pouring, reverse mould, etc. Particle size C and D are recommended for printing, coating, injection, etc. Particle size E and F are recommended for printing, wiredrawing, etc.

3. Yellow green photoluminescent pigment the most widely known and used glow in the dark powder, and has many derivative products including glow in the dark paint, ink, resin, plastic, fire-fighting safety signs, fishing tool, craftworks and gifts, and so on.

CERTIFICATIONS

MH serie's photoluminescent pigment meets the US requirement of ASTM F963-16 (Standard Consumer Safety Specification on Toy Safety), Test Method CPSC-CH-E1003-09.1 for total Lead, and ASTM F 963-16 (Clause 8.3) for soluable heavy metal; and registered for EU REACH standard in accordance with the REACH regulation (EC) No 1907/2006.

PHYSICAL PROPERTY

| Produce code: | MHG | Appearance: | Solid powder |

| Chemical name: | Strontium aluminate doped with rare earth | PH: | 10~12 |

| Molecular formula: | SrAl2O4:Eu+2,Dy+3 | density: | 3.4 g/cm3 |

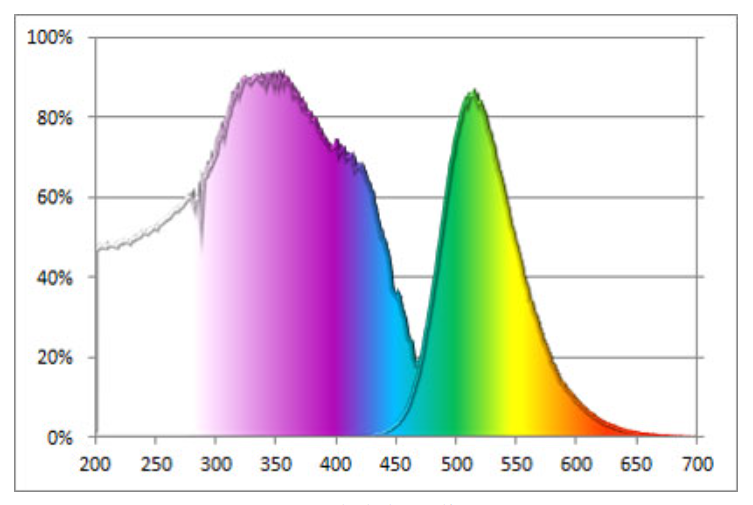

| CAS No.: | 12004-37-4 | Excitation wavelength: | 240~440nm |

| Daytime color: | Light yellow | Emitting wavelength: | 520nm |

| Glowing color: | Yellow-green | HS code: | 3206500 |

EXICITATION EMISSION SPECTRUM

ADDITIONAL INFORMATION

We now owns 5 production lines of photoluminescent pigment and has the annual capacity to manufacture 500 tons of pigment. Our R&D team can also help you to develop a unique type of pigment that fully suits your application, with customized luminance level, glow length, grain size and color. We have 20 years experience of exporting and our photoluminescent matierals and products are loved by customers from all over the globe.